Unlock Material Secrets: What's Yield Strength?

Understanding material behavior under stress is critical in engineering design. Finite Element Analysis (FEA) platforms, such as Ansys, rely on accurate material properties, including what is the yield strength of a material, to predict structural integrity. The yield strength itself represents the stress level at which a material begins to deform permanently; exceeding this point risks failure. Professionals at organizations like ASTM International develop standardized testing methods to accurately determine this essential mechanical property for various materials. This knowledge empowers engineers to design safer and more reliable structures.

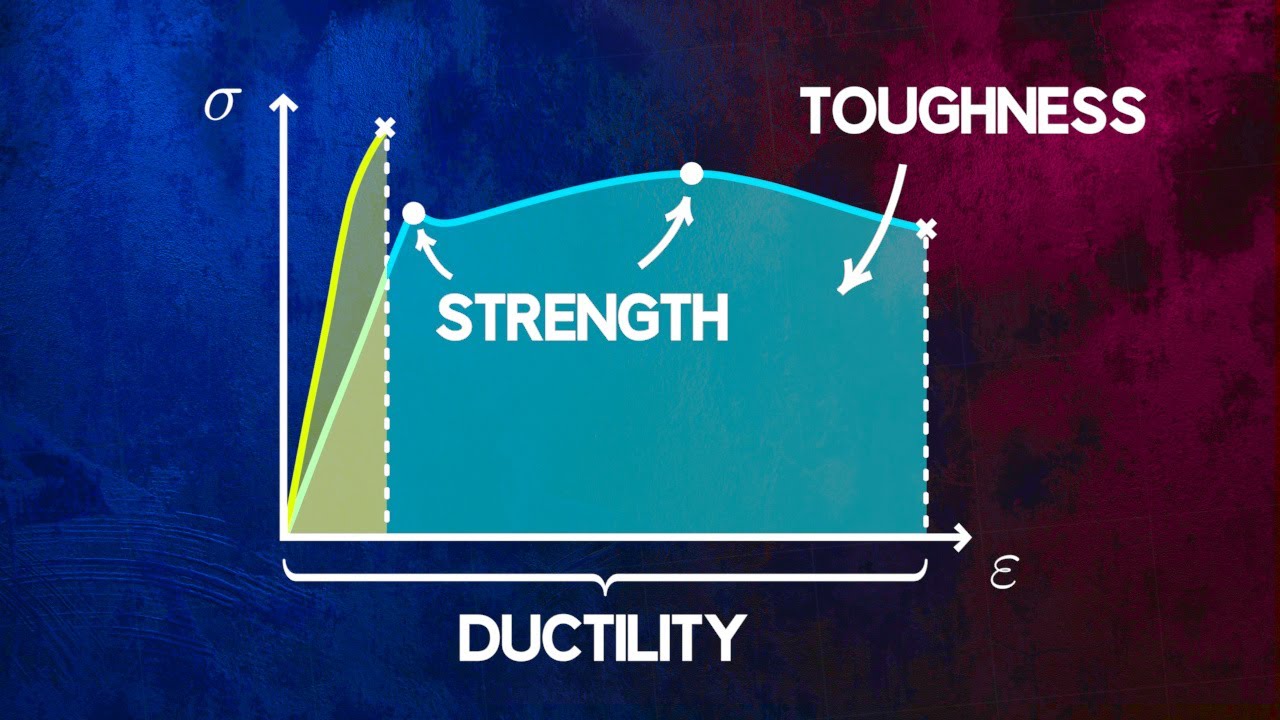

Image taken from the YouTube channel The Efficient Engineer , from the video titled Understanding Material Strength, Ductility and Toughness .

Unlock Material Secrets: What's Yield Strength?

Understanding the mechanical properties of materials is crucial for engineers, designers, and anyone working with physical objects. One of the most important of these properties is yield strength. But what is the yield strength of a material? This article breaks down this concept, explaining its meaning, significance, and how it’s determined.

Defining Yield Strength

Simply put, yield strength is the amount of stress a material can withstand before it begins to deform permanently. This is a critical threshold. Below the yield strength, the material will return to its original shape once the stress is removed (elastic deformation). Above it, the material will be permanently altered (plastic deformation).

Elastic vs. Plastic Deformation

-

Elastic Deformation: Think of stretching a rubber band slightly. When you release it, it snaps back to its original length. This is elastic deformation. The material hasn't fundamentally changed.

-

Plastic Deformation: Now imagine bending a paperclip. It will remain bent even after you stop applying force. This is plastic deformation. The material's structure has been permanently altered.

Why is Yield Strength Important?

Yield strength is a vital parameter in engineering design. Knowing the yield strength of a material allows engineers to:

- Ensure structures and components can withstand expected loads without permanent damage.

- Select appropriate materials for specific applications where permanent deformation is unacceptable.

- Predict the behavior of materials under stress.

- Prevent catastrophic failures caused by exceeding the material's elastic limit.

Understanding Stress and Strain

To fully grasp yield strength, it’s essential to understand the concepts of stress and strain.

Stress

Stress is the force applied per unit area of a material. It’s a measure of the internal forces that molecules within a continuous material exert on each other.

- Units: Common units for stress are Pascals (Pa) or pounds per square inch (psi).

- Types of Stress:

- Tensile Stress: Pulling or stretching force.

- Compressive Stress: Pushing or squeezing force.

- Shear Stress: Force applied parallel to a surface.

Strain

Strain is the measure of deformation of the material as a response to stress. It is dimensionless and often expressed as a percentage.

- Calculation: Strain is calculated as the change in length divided by the original length.

- Types of Strain: Correspond to the types of stress (tensile, compressive, shear).

Determining Yield Strength: The Stress-Strain Curve

The yield strength of a material is typically determined by creating a stress-strain curve. This curve is generated by subjecting a material sample to a controlled tensile test and measuring the stress and corresponding strain.

The Shape of the Curve

The stress-strain curve typically exhibits the following regions:

- Elastic Region: The initial portion of the curve is linear. In this region, stress is proportional to strain (Hooke's Law). The material deforms elastically.

- Yield Point: The point where the curve starts to deviate significantly from the linear relationship. This indicates the onset of plastic deformation.

- Plastic Region: The curve becomes nonlinear. In this region, the material undergoes permanent deformation.

- Ultimate Tensile Strength: The maximum stress the material can withstand before it begins to neck (localize deformation).

- Fracture Point: The point at which the material breaks.

Determining Yield Strength for Different Materials

The method for determining yield strength can vary slightly depending on the material and the shape of the stress-strain curve.

-

Materials with a Well-Defined Yield Point: Some materials, like mild steel, exhibit a distinct "yield point" on the stress-strain curve. This point is easily identifiable and represents the yield strength.

-

Materials Without a Well-Defined Yield Point: Many materials, such as aluminum and high-strength steel, do not have a clearly defined yield point. In these cases, the offset method is used.

- Offset Method: A line is drawn parallel to the linear portion of the stress-strain curve, offset by a specified strain value (typically 0.2% or 0.002). The stress value where this offset line intersects the stress-strain curve is defined as the yield strength. This is often referred to as the 0.2% offset yield strength.

Factors Affecting Yield Strength

Several factors can influence the yield strength of a material:

- Temperature: Higher temperatures generally decrease yield strength.

- Strain Rate: The rate at which stress is applied. Higher strain rates can increase yield strength.

- Grain Size: Smaller grain sizes typically increase yield strength (Hall-Petch relationship).

- Impurities and Alloying Elements: Adding alloying elements can significantly alter the yield strength.

- Cold Working: Deforming a metal at room temperature can increase its yield strength through work hardening.

Typical Yield Strength Values (Examples)

The following table provides examples of typical yield strength values for different materials. Note that these values are approximate and can vary depending on the specific alloy, processing method, and other factors.

| Material | Yield Strength (MPa) | Yield Strength (psi) |

|---|---|---|

| Mild Steel | 250 | 36,000 |

| Aluminum Alloy (6061-T6) | 276 | 40,000 |

| Stainless Steel (304) | 205 | 30,000 |

| Titanium Alloy (Ti-6Al-4V) | 830 | 120,000 |

| High-Density Polyethylene (HDPE) | 26-33 | 3,800-4,800 |

Understanding what is the yield strength of a material, the factors that influence it, and how it's determined are critical for selecting the right materials for any application and ensuring the safety and reliability of structures and components.

Video: Unlock Material Secrets: What's Yield Strength?

FAQs About Yield Strength

Here are some frequently asked questions to help you better understand yield strength and its importance in materials science.

Why is yield strength important?

Yield strength is crucial because it tells engineers the maximum stress a material can withstand without permanent deformation. Knowing what is the yield strength of a material helps ensure structures and components won't bend or break under intended loads. This prevents failures and ensures safety.

What's the difference between yield strength and tensile strength?

Yield strength marks the point where permanent deformation begins, while tensile strength is the point where a material starts to neck and ultimately fracture. Tensile strength is always higher than yield strength. Understanding what is the yield strength of a material is vital for preventing permanent damage, while knowing tensile strength tells you how close it is to breaking.

How is yield strength measured?

Yield strength is typically determined through a tensile test. A sample is pulled until it starts to deform permanently. The stress at this point is recorded as the yield strength. The specific methodology depends on the material and application. What is the yield strength of a material is often provided in a material's datasheet.

Is a higher yield strength always better?

Not necessarily. While a high yield strength indicates a material can withstand more stress without deforming, other factors like ductility, toughness, and cost are also important. A material with high yield strength but low ductility might be brittle and prone to fracture. The best choice depends on the specific application and its requirements.